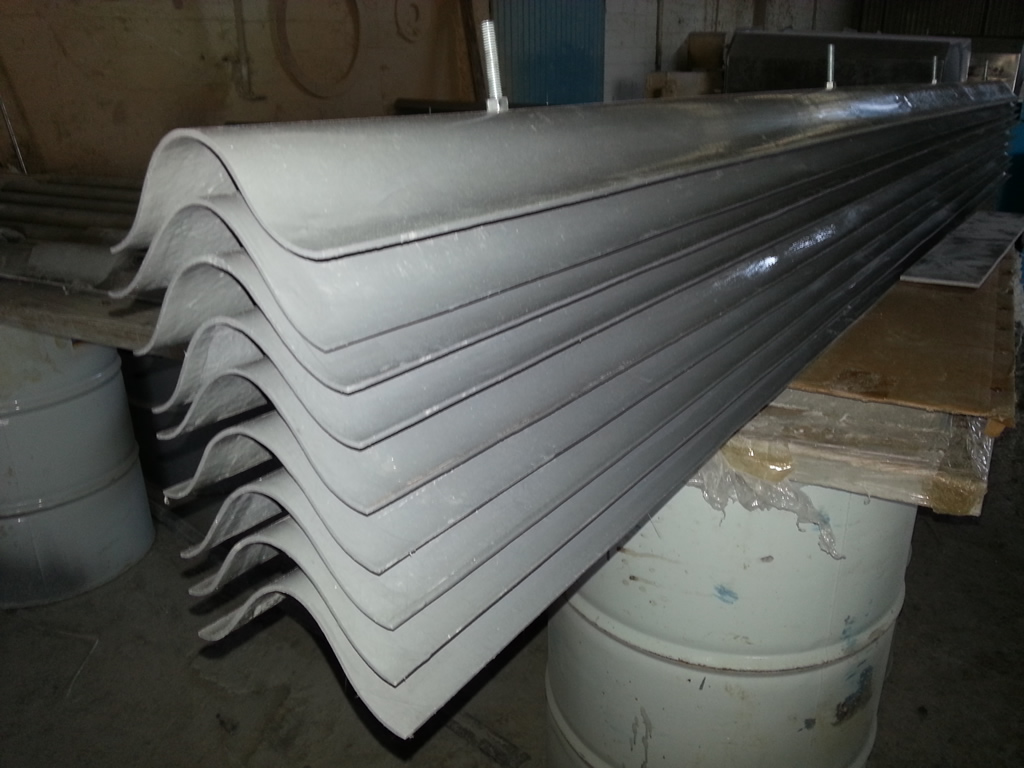

Cooling Towers

1. Description: A cooling tower is a mechanical device for cooling a certain volume of water. Cooling temperature is defined based on the temperature of hot water that would be at the entrance of the tower, the desired temperature at the exit of the tower and the wet bulb temperature that is taken in the area in which the tower will be placed. Due to the diversity of construction materials for both external and internal parts of cooling towers, it is recommended to know the specifics of what is required to offer the best technical / economic alternative.

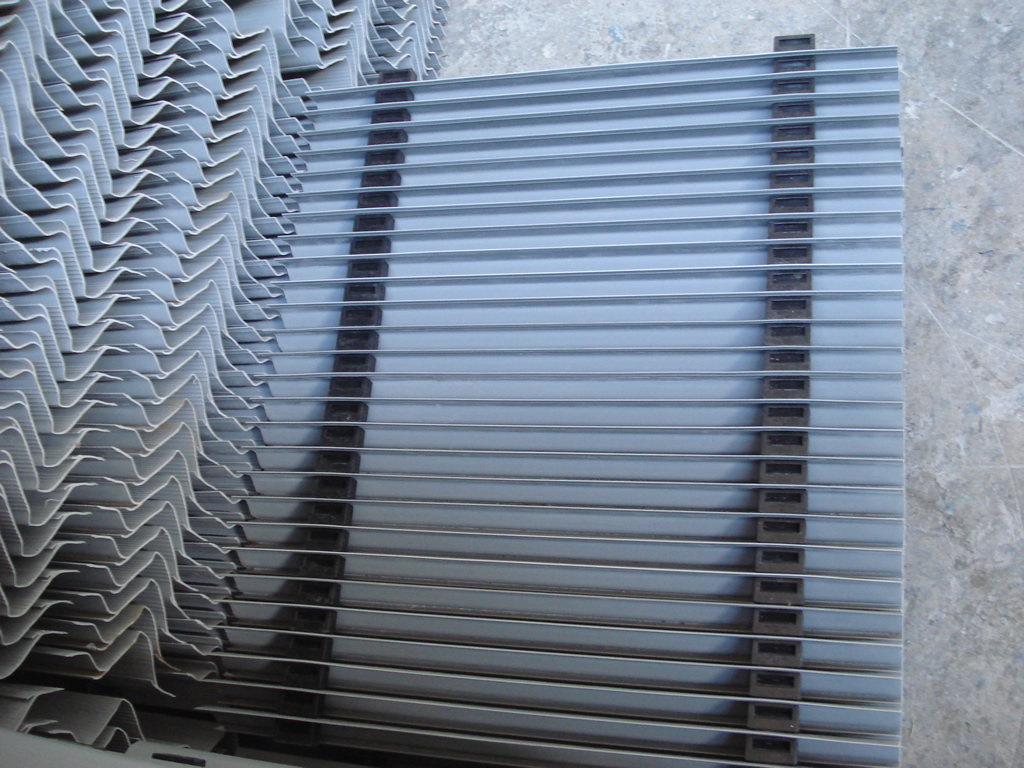

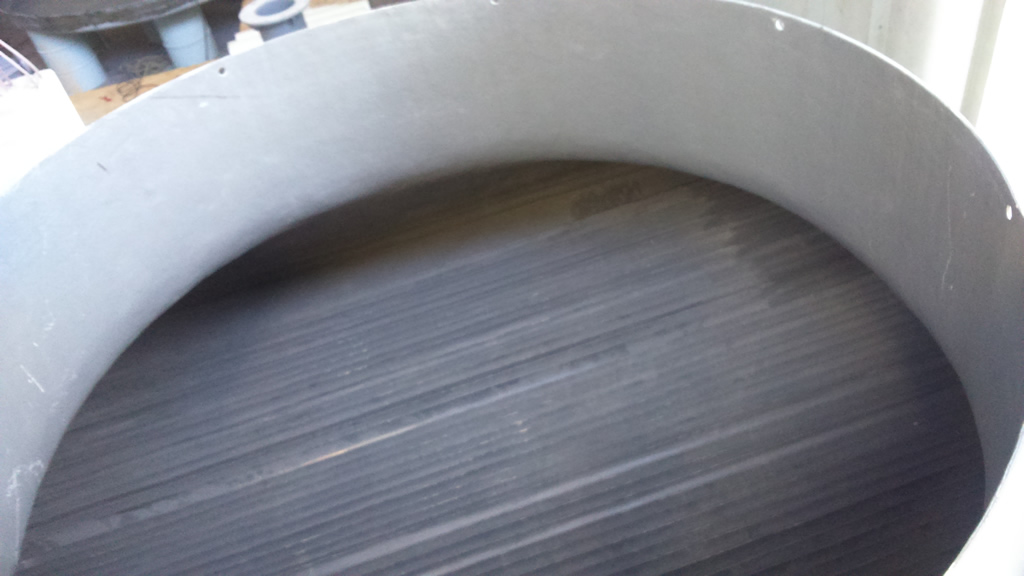

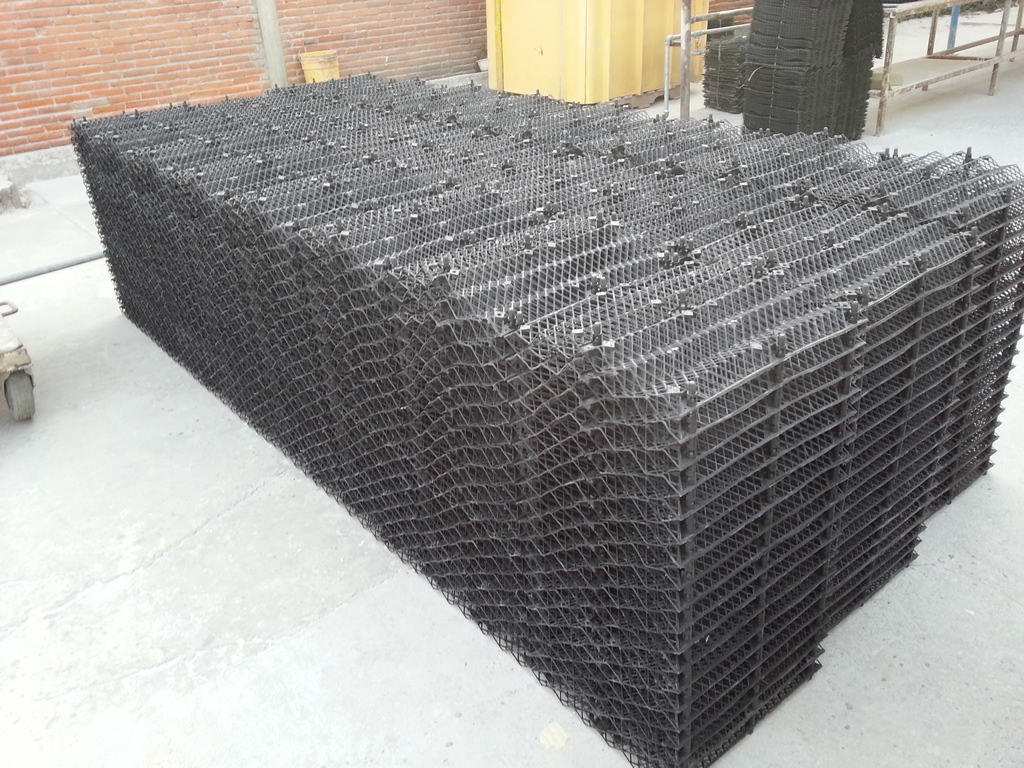

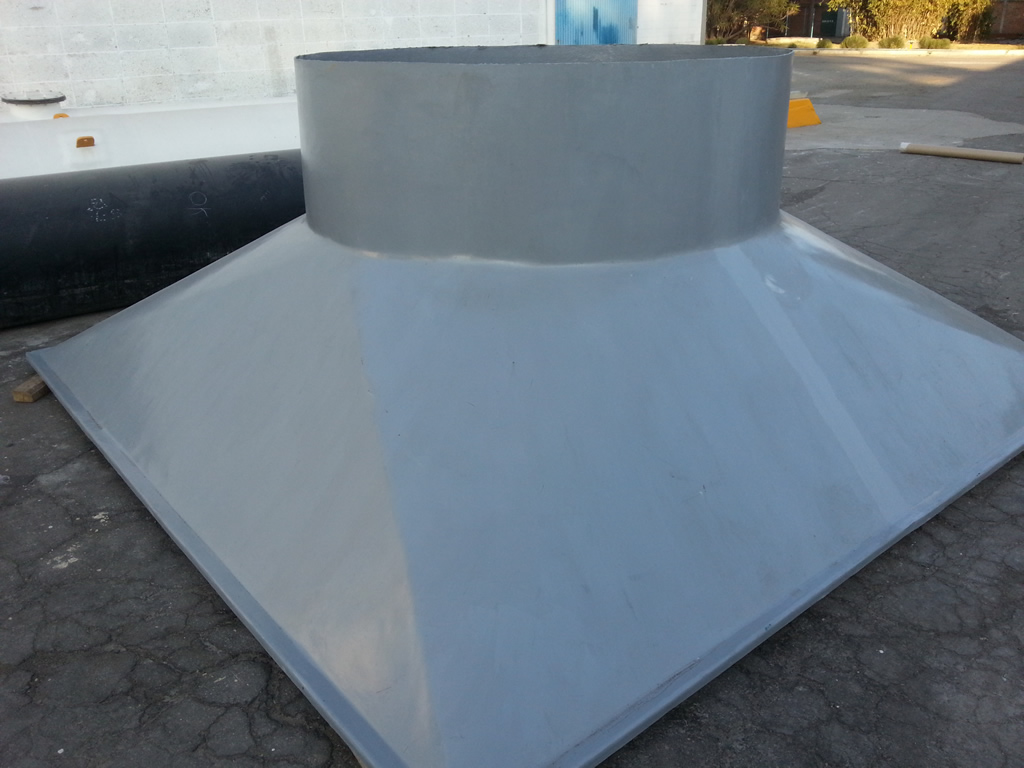

Lapsolite, as of the 1980´s, in partnership with the German company Balcke-Dürr (who at the time has the largest share in the European market for cooling towers), began to market cooling towers in the domestic market since it had acquired very important contributions in technology, design and construction of cooling towers from this partnership. In recent years, based on new developments of internal components, Lapsolite has integrated these improvements in its designs, so that in more recent years it has achieved better designs, thus having an impact on the best efficiency during the water cooling process, which has led Lapsolite to export cooling towers to different parts of the world.

2. Ranges of design: Different alternatives according to the volumes of water to be cooled are offered:

- SG series:

- KE series:

- RS series:

And modular systems can be offered to cover the desired cooling flow.

3. Applications: Industrial plants (metallurgical, chemical, pharmaceutical, etc.) shopping centers, hospitals.

4. Benefits:

a. Low operation and maintenance costs

b. Low to moderate investment depending on the construction materials

ENGLISH

ENGLISH